Products and Features

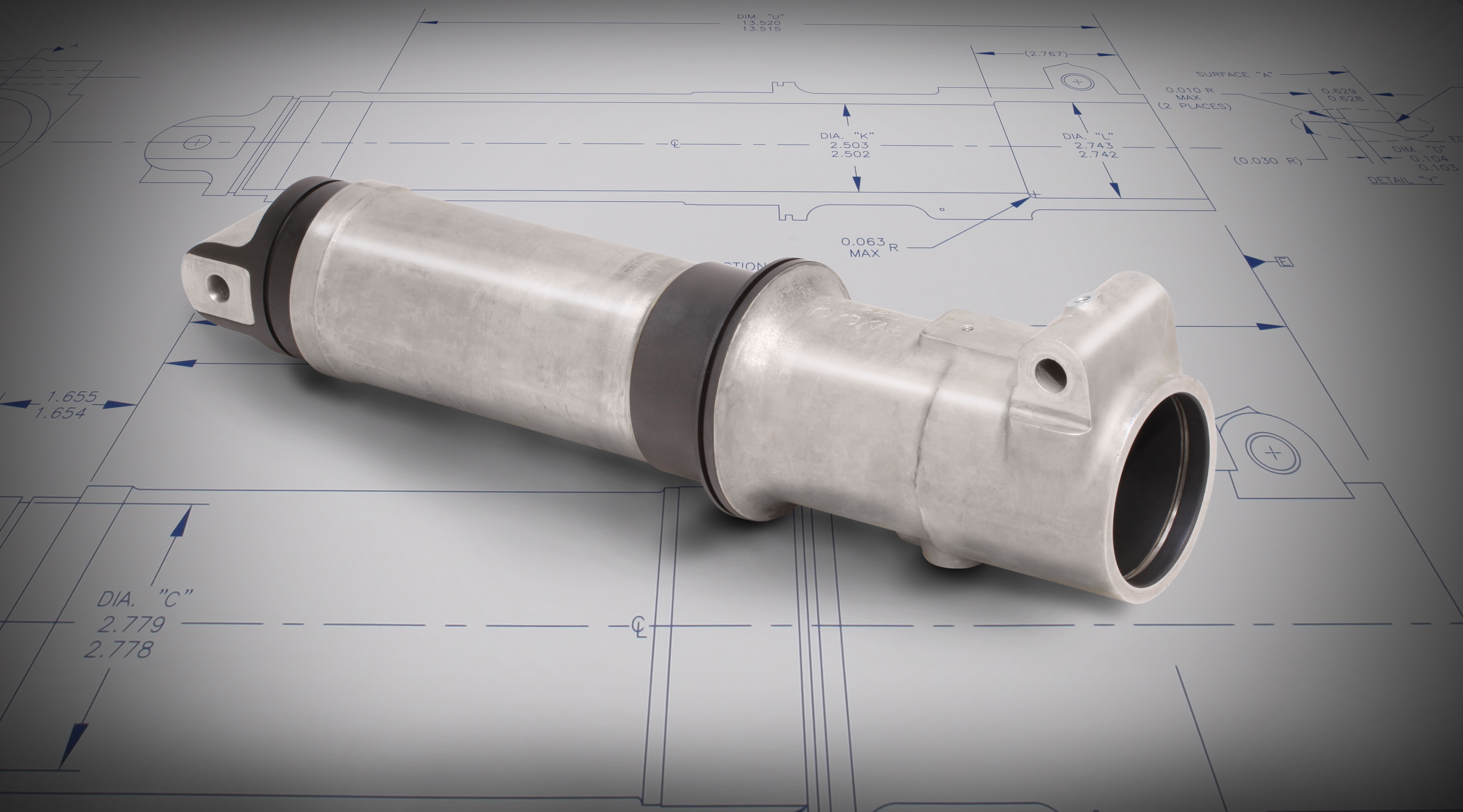

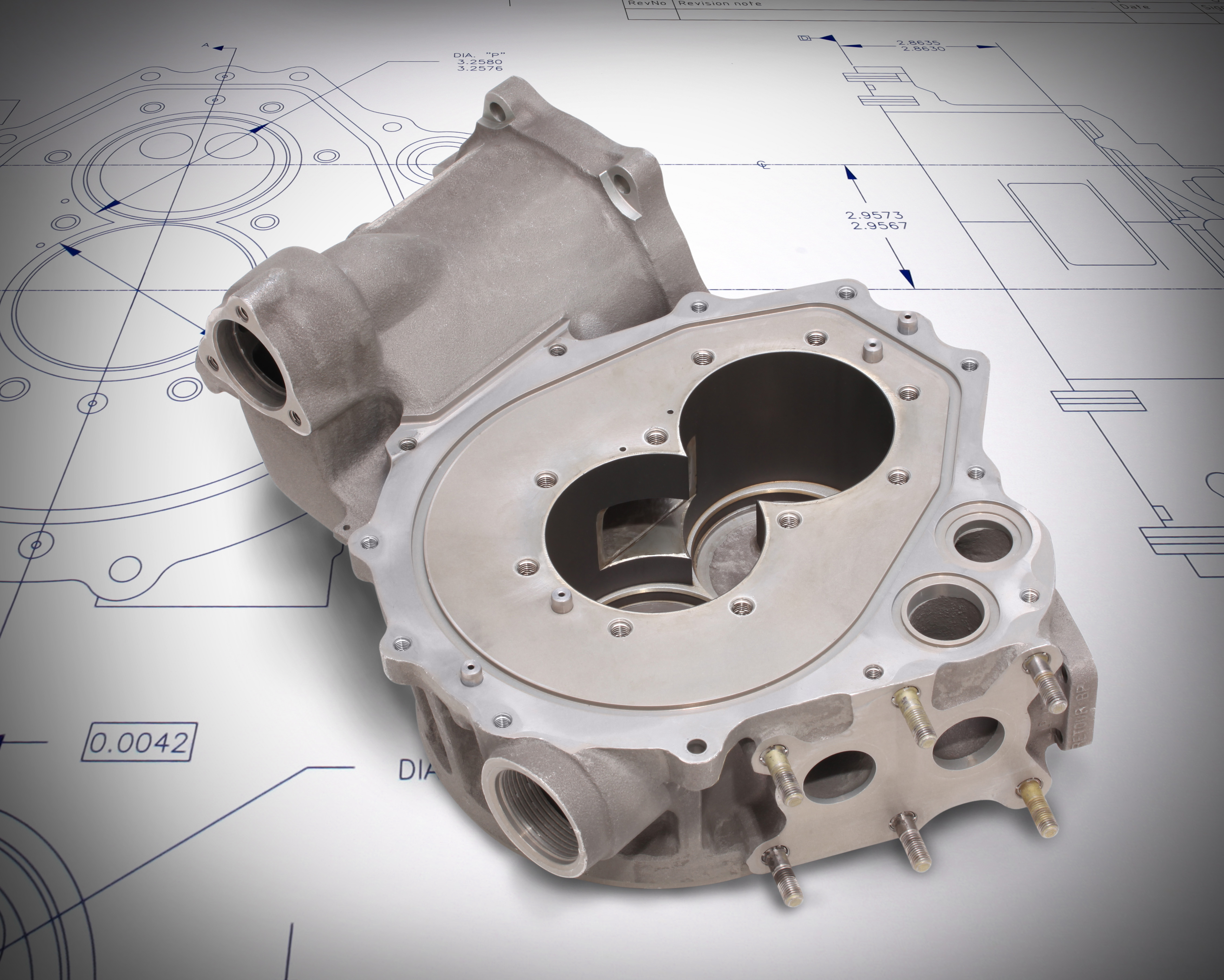

EPOLY®

Is a one part thixotropic material that, when cured, is a hard as mild steel and can be readily machined to OEM specifications and tolerances.

EPOLY®

Reliable Performance Achieved Economically Savings up to 85% versus purchasing new replacement Application thickness capability over .200” A variety of metals can be repaired

EPOLY®

Can be applied to almost any material that can withstand 300°F cure temperature. The two ideal materials are aluminum and magnesium due to their expansion and contraction similarities to EPOLY®

EPOLY®

Has lubricated properties of its own. Mating surfaces, when coated with EPOLY®, will often outlast the original surfaces in the same service.

EPOLY®

Superior bond strength Self Lubricating Compatibility with fuels, hydraulic fluids and other lubricants Operating Temperature Range: -65°F to 450°F

EPOLY®

EPOLY® repairs can be made repeatedly, as long as the parent materials retains its structural integrity. It is an exceptional and economic repair method fro worn, damaged and/or out of tolerance parts.

EPOLY®

Does not soften or dissolve when exposed to jet fuels, hydraulic fluids (including Skydrol), oils or greases.

EPOLY®

Cavitation resistance Inhibits corrosion Unlimited repeat repairs Operates at pressure up to 3,500 PSI and speeds up to 100 ft/min

EPOLY®

Maintains its adherence and integrity under extreme temperatures from -65°F to 400°F, and under high pressure and considerable mechanical forces.

Product Feature

Product Feature